Further Ball Mills

FURTHER PRODUCT GROUPS

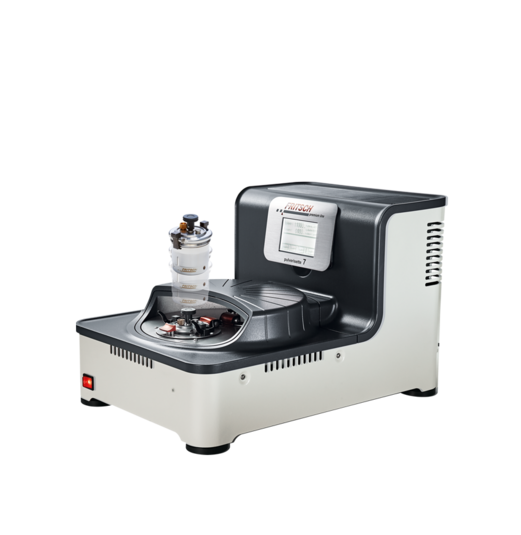

Please note: For the Mini-Mill you require 1 grinding bowl and the corresponding number of grinding balls. To avoid undesired contamination of the sample through abrasion, we offer a selection of 4 different material types. Normally, grinding bowls and balls of the same material are used. In principle, the grinding bowl material must be harder than the material to be ground.

Grinding bowls and grinding balls made of zirconium oxide for absolute metal-free grinding are also offered. Important: please keep in mind the specified useful capacity as this is not identical to the bowl volume.

GRINDING BOWLS

-

Material data for the grinding bowls/balls

Material Main component of the material Density g/cm³ Abrasion resistance Used for grinding material Zirconium oxide ZrO2 5.7 very good Fibrous, abrasive samples Hardened, stainless steel Fe – Cr 7.7 good Hard, medium-hard, brittle samples PTFE CxF2x 2.16 sufficient Frozen tissue samples PCR tube gentle extremely small quantities in the biological field -

Size of the grinding balls

Type of feed material Ball diameter Hard samples with a maximum feed size of 2 - 5 mm 15 mm Fine materials 0.5 mm 10 mm or 5 mm Homogenisation of dry or liquid samples 10 mm or 5 mm Grinding of extremely small sample quantities, primarily in the biological field 1 mm -

Recommended number of balls per grinding bowl

Grinding bowl/

Useful capacity (sample volume)30 ml

1 – 15 ml15 ml

0.5 – 5 ml10 ml

0.2 – 1 ml5 ml

0.1 – 1 ml2 ml

Single use1.5 ml

Single use0.5 ml

Single useBalls diameter 15 mm 4 2 1 10 mm 10 5 3 1 5 mm 120 60 30 20 1 mm 40 g 12 g 8 g 5 g 2 g 1 g < 1 g -

Additional Information

The specified ball filling per bowl is the minimum quantity and should possibly be increased depending on the material properties. The useful capacity depends on the type of material. In exceptional cases, the number of grinding balls can be reduced by up to 15 %. However, increased abrasion should be expected. In general, smaller grinding balls achieve finer grinding results.

Normally, grinding bowls and balls of the same material are used. In principle, the grinding bowl materials must be harder than the material to be ground. Important: Pay attention to the specified useful capacity as this is not identical to the bowl volume!

It may also be useful to work here with grinding balls ≤ 3 mm diameter. We have not listed these here because we would like to advise you regarding your application. Please contact Mr. Benes our laboratory supervisor.

Please select 1 grinding bowl, which is offered in the sizes 30 ml, 15 ml, 10 ml and 5 ml or the container for single-use tubes to perfectly match your sample volume. The useful capacity of the grinding bowls can be found in the selection aid. For biotechnological use the PTFE bowl 5 ml and for smaller quantities the container for single-use tubes is especially suitable. For best grinding results the grinding bowls are available in different materials thus directly preventing contamination of the samples as a result of undesired abrasion.

GRINDING BOWL 30 ML

Grinding bowl with lid and seal ring

Grinding bowl volume: 30 ml

Useful capacity: 1 ... 10 ml

Weight net: 0.072 kg

This special grinding bowl is primarily used to grind organic samples, like for example deep freeze tissue, cells, foodstuffs etc.. The entire bowl can be pre-cooled in liquid nitrogen. Afterwards the sample is subsequently comminuted in sub-zero temperature.

Please keep in mind: A separate bowl holder order no. 23.1441.00 is required for use in the Mini-Mill.

| General specifications | |

| Material | PTFE |

| CAS Number | 9002-84-0 |

| Chemical composition | |||||||

| Element | Formula | ||||||

| Polytetrafluoroethylene | C 2F4 | ||||||

| Melting point | 327° C | ||||||

| Max. application temp. constant | 260° C | ||||||

| Max. application temp. briefly | 300° C | ||||||

| Physical and mechanical properties | |

| Density | 2.16 g /cm³ |

| Ball pressure hardness | ISO 868, ISO 2039-2, D 55 Shore |

Holder for grinding bowl PTFE 30 ml - order no. 23.1440.00

GRINDING BOWL 15 ML

Grinding bowl with lid and seal ring

Grinding bowl volume: 15 ml

Useful capacity: 0.5 … 5 ml

Weight net: 0.065 kg

General material specification:

Material: zirconium oxide - ZrO2

Abrasion resistance: very good

Suitable for: fibrous, abrasive samples

Detailed information about the material you will find in the element analysis.

| General specifications | |

| Material | Zirconium oxide - ZrO2 |

| Chemical composition | |

| Element | Share % |

| Zirconium oxide – ZrO2 | 94.2 - 95.2 |

| Hafnium oxide – HfO2 | 1 - 2 |

| Magnesium oxide – MgO | 3.5 |

| Silicon dioxide – SiO | 0.1 |

| Aluminium oxide – Al2O3 | 0.1 |

| Other | 0.1 |

| Physical and mechanical properties | |

| Density | 5.7 g/cm³ |

| Hardness Vickers | 1200 (HV10) |

Explanations on hardness data

Grinding bowl with lid and seal ring

Grinding bowl volume: 15 ml

Useful capacity: 0.5 … 5 ml

Weight net: 0.056 kg

General material specification:

Material: hardened, stainless steel - 1.4125

Abrasion resistance: good

Suitable for: hard, brittle samples

Detailed information about the material you will find in the element analysis.

| General specifications | |

| Material | hardened stainless steel – 1.4125 |

| ISO/EN/DIN code | X105CrMo17 |

| Chemical composition | |

| Element | Share % |

| Iron– Fe | 81.4 |

| Chromium – Cr | 17 |

| Carbon – C | 1.1 |

| Molybdenum – Mo | 0.5 |

| Physical and mechanical properties | |

| Density | 7.7 kg/dm³ |

| Hardness | ~ 60 HRC |

Explanations on hardness data

GRINDING BOWL 10 ML

Grinding bowl with lid and seal ring

Grinding bowl volume: 10 ml

Useful capacity: 0.2 … 1 ml

Weight net: 0.054 kg

General material specification:

Material: zirconium oxide - ZrO2

Abrasion resistance: very good

Suitable for: fibrous, abrasive samples

Detailed information about the material you will find in the element analysis.

| General specifications | |

| Material | Zirconium oxide - ZrO2 |

| Chemical composition | |

| Element | Share % |

| Zirconium oxide – ZrO2 | 94.2 - 95.2 |

| Hafnium oxide – HfO2 | 1 - 2 |

| Magnesium oxide – MgO | 3.5 |

| Silicon dioxide – SiO | 0.1 |

| Aluminium oxide – Al2O3 | 0.1 |

| Other | 0.1 |

| Physical and mechanical properties | |

| Density | 5.7 g/cm³ |

| Hardness Vickers | 1200 (HV10) |

Explanations on hardness data

Grinding bowl with lid and seal ring

Grinding bowl volume: 10 ml

Useful capacity: 0.2 … 1 ml

Weight net: 0.045 kg

General material specification:

Material: hardened stainless steel - 1.4125

Abrasion resistance: good

Suitable for: hard, brittle samples

Detailed information about the material you will find in the element analysis.

| General specifications | |

| Material | hardened stainless steel – 1.4125 |

| ISO/EN/DIN code | X105CrMo17 |

| Chemical composition | |

| Element | Share % |

| Iron– Fe | 81.4 |

| Chromium – Cr | 17 |

| Carbon – C | 1.1 |

| Molybdenum – Mo | 0.5 |

| Physical and mechanical properties | |

| Density | 7.7 kg/dm³ |

| Hardness | ~ 60 HRC |

Explanations on hardness data

GRINDING BOWL 5 ML

Grinding bowl with lid and seal ring

Grinding bowl volume: 5 ml

Useful capacity: 0.1 … 1 ml

Weight net: 0.050 kg

This special grinding bowl in combination with a 10 mm steel grinding ball is primarily used to grind biological sample, like for example deep freeze tissue, cells, etc.. The entire bowl can be pre-cooled in liquid nitrogen. Afterwards the sample is subsequently comminuted in sub-zero temperature.

| General specifications | |

| Material | PTFE |

| CAS Number | 9002-84-0 |

| Chemical composition | |||||||

| Element | Formula | ||||||

| Polytetrafluoroethylene | C 2F4 | ||||||

| Melting point | 327° C | ||||||

| Max. application temp. constant | 260° C | ||||||

| Max. application temp. briefly | 300° C | ||||||

| Physical and mechanical properties | |

| Density | 2.16 g /cm³ |

| Ball pressure hardness | ISO 868, ISO 2039-2, D 55 Shore |

Container for single-use tubes

Container incl. 6 tubes à 0.5 ml, 1.5 ml and 2 ml volume

For grinding extremely small sample quantities, primarily in the biological field. This tube container is available for up to six 0.5 ml, 1.5 ml or 2 ml PCR tubes. The samples to be

tested are usually available in liquid form, can be assessed very quickly and gently in the individual tubes with 1 mm grinding balls.

GRINDING BALLS

-

Material data for the grinding bowls/balls

Material Main component of the material Density g/cm³ Abrasion resistance Used for grinding material Zirconium oxide ZrO2 5.7 very good Fibrous, abrasive samples Hardened, stainless steel Fe – Cr 7.7 good Hard, medium-hard, brittle samples PTFE CxF2x 2.16 sufficient Frozen tissue samples PCR tube gentle extremely small quantities in the biological field -

Size of the grinding balls

Type of feed material Ball diameter Hard samples with a maximum feed size of 2 - 5 mm 15 mm Fine materials 0.5 mm 10 mm or 5 mm Homogenisation of dry or liquid samples 10 mm or 5 mm Grinding of extremely small sample quantities, primarily in the biological field 1 mm -

Recommended number of balls per grinding bowl

Grinding bowl/

Useful capacity (sample volume)30 ml

1 – 15 ml15 ml

0.5 – 5 ml10 ml

0.2 – 1 ml5 ml

0.1 – 1 ml2 ml

Single use1.5 ml

Single use0.5 ml

Single useBalls diameter 15 mm 4 2 1 10 mm 10 5 3 1 5 mm 120 60 30 20 1 mm 40 g 12 g 8 g 5 g 2 g 1 g < 1 g -

Additional Information

The specified ball filling per bowl is the minimum quantity and should possibly be increased depending on the material properties. The useful capacity depends on the type of material. In exceptional cases, the number of grinding balls can be reduced by up to 15 %. However, increased abrasion should be expected. In general, smaller grinding balls achieve finer grinding results.

Normally, grinding bowls and balls of the same material are used. In principle, the grinding bowl materials must be harder than the material to be ground. Important: Pay attention to the specified useful capacity as this is not identical to the bowl volume!

It may also be useful to work here with grinding balls ≤ 3 mm diameter. We have not listed these here because we would like to advise you regarding your application. Please contact Mr. Benes our laboratory supervisor.

For achieving best grinding result grinding balls are available in ≤ 3 mm - 15 mm diameters and in 2 different materials, thus directly preventing contamination of the samples as a result of undesired abrasion. The recommended number of balls per grinding bowl can be found in the selection aid.

GRINDING BALLS 15 MM DIAMETER FOR GRINDING BOWL 15 ML, 10 ML

General material specification:

Material: zirconium oxide - ZrO2

Abrasion resistance: very good

Suitable for: fibrous, abrasive samples

| General specifications | |

| Material | Zirconium oxide - ZrO2 |

| Chemical composition | |

| Element | Share % |

| Zirconium oxide – ZrO2 | 94.2 - 95.2 |

| Hafnium oxide – HfO2 | 1 - 2 |

| Magnesium oxide – MgO | 3.5 |

| Silicon dioxide – SiO | 0.1 |

| Aluminium oxide – Al2O3 | 0.1 |

| Other | 0.1 |

| Physical and mechanical properties | |

| Density | 5.7 g/cm³ |

| Hardness Vickers | 1200 (HV10) |

Explanations on hardness data

General material specification:

Material: hardened, stainless steel - Fe-Cr

Abrasion resistance: good

Suitable for: medium-hard, brittle samples

| General specifications | |

| Material | hardened stainless steel – 1.4125 |

| ISO/EN/DIN code | X105CrMo17 |

| Chemical composition | |

| Element | Share % |

| Iron– Fe | 81.4 |

| Chromium – Cr | 17 |

| Carbon – C | 1.1 |

| Molybdenum – Mo | 0.5 |

| Physical and mechanical properties | |

| Density | 7.7 kg/dm³ |

| Hardness | ~ 60 HRC |

Explanations on hardness data

GRINDING BALLS 10 MM DIAMETER FOR GRINDING BOWL 15 ML, 10 ML, 5 ML

General material specification:

Material: zirconium oxide - ZrO2

Abrasion resistance: very good

Suitable for: fibrous, abrasive samples

| General specifications | |

| Material | Zirconium oxide - ZrO2 |

| Chemical composition | |

| Element | Share % |

| Zirconium oxide – ZrO2 | 94.2 - 95.2 |

| Hafnium oxide – HfO2 | 1 - 2 |

| Magnesium oxide – MgO | 3.5 |

| Silicon dioxide – SiO | 0.1 |

| Aluminium oxide – Al2O3 | 0.1 |

| Other | 0.1 |

| Physical and mechanical properties | |

| Density | 5.7 g/cm³ |

| Hardness Vickers | 1200 (HV10) |

Explanations on hardness data

General material specification:

Material: hardened, stainless steel - Fe-Cr

Abrasion resistance: good

Suitable for: hard, medium-hard, brittle samples

| General specifications | |

| Material | hardened stainless steel – 1.4125 |

| ISO/EN/DIN code | X105CrMo17 |

| Chemical composition | |

| Element | Share % |

| Iron– Fe | 81.4 |

| Chromium – Cr | 17 |

| Carbon – C | 1.1 |

| Molybdenum – Mo | 0.5 |

| Physical and mechanical properties | |

| Density | 7.7 kg/dm³ |

| Hardness | ~ 60 HRC |

Explanations on hardness data

GRINDING BALLS 5 MM DIAMETER FOR GRINDING BOWL 15 ML, 10 ML, 5 ML

General material specification:

Material: zirconium oxide - ZrO2

Abrasion resistance: very good

Suitable for: fibrous, abrasive samples

100 grinding balls made of zirconium oxide with 5 mm dia. weigh approx. 38 g.

With the weight information, the high number of balls per grinding bowl can be determined by weighing.

| General specifications | |

| Material | Zirconium oxide ZrO2 |

| ISO/EN/DIN code | |

| Chemical composition | |

| Element | Share % |

| Zirconium oxide - ZrO2 | 95% |

| Yttrium oxide -Y2O3 | 5% |

| Physical and mechanical properties | |

| Density | 6.0 g/cm³ |

| Hardness Vickers | 1300 (HV10) |

Explanations on hardness data

General material specification:

Material: hardened, stainless steel - Fe-Cr

Abrasion resistance: good

Suitable for: hard, medium-hard, brittle samples

100 grinding balls made of hardened, stainless steel with 5 mm dia. weigh approx. 52 g.

With the weight information, the high number of balls per grinding bowl can be determined by weighing.

| General specifications | |

| Material | hardened stainless steel – 1.4125 |

| ISO/EN/DIN code | X105CrMo17 |

| Chemical composition | |

| Element | Share % |

| Iron– Fe | 81.4 |

| Chromium – Cr | 17 |

| Carbon – C | 1.1 |

| Molybdenum – Mo | 0.5 |

| Physical and mechanical properties | |

| Density | 7.7 kg/dm³ |

| Hardness | ~ 60 HRC |

Explanations on hardness data

GRINDING BALLS 1 MM DIAMETER FOR SINGLE-USE TUBES

General material specification:

Material: zirconium oxide - ZrO2

Abrasion resistance: very good

Suitable for: fibrous, abrasive samples

Grinding balls made of zirconium oxide with 1 mm dia. are packed in 100 g units and must be weight out. In the selection aid you can find the required mass per grinding bowl.

| General specifications | |

| Material | Zirconium oxide ZrO2 |

| ISO/EN/DIN code | |

| Chemical composition | |

| Element | Share % |

| Zirconium oxide - ZrO2 | 95% |

| Yttrium oxide -Y2O3 | 5% |

| Physical and mechanical properties | |

| Density | 6.0 g/cm³ |

| Hardness Vickers | 1300 (HV10) |

Explanations on hardness data

General material specification:

Material: hardened, stainless steel - Fe-Cr

Abrasion resistance: good

Suitable for: hard, medium-hard, brittle samples

Grinding balls made of hardened, stainless steel with 1 mm dia. are packed in 100 g units and must be weight out.

In the selection aid you can find the required mass per grinding bowl.

| General specifications | |

| Material | hardened stainless steel – 1.4125 |

| ISO/EN/DIN code | X105CrMo17 |

| Chemical composition | |

| Element | Share % |

| Iron– Fe | 81.4 |

| Chromium – Cr | 17 |

| Carbon – C | 1.1 |

| Molybdenum – Mo | 0.5 |

| Physical and mechanical properties | |

| Density | 7.7 kg/dm³ |

| Hardness | ~ 60 HRC |

Explanations on hardness data

Certification

IQ/OQ documentation for the independent utilization for the support of instrument qualification in the quality management system for the Mini-Mill PULVERISETTE 23.

certification

IQ/OQ documentation (questionnaire format - implementation by customer) for the independent utilization for the support of instrument qualification in the quality management system for the Mini-Mill PULVERISETTE 23.